Research Centre

Overview

The Research Centre of the Mechanical Department at Loyola-ICAM College of Engineering and Technology (LICET) stands as a beacon of innovation and academic excellence within the realm of mechanical engineering. Recognized and endorsed by the prestigious Center for Research, Anna University, our center is committed to fostering cutting-edge research, nurturing budding talent, and contributing to the advancement of mechanical engineering knowledge.

Research Focus Areas: Our research center encompasses a diverse array of focus areas within mechanical engineering, including but not limited to:

- Fablab

- Coordinate measuring machine

- Solar power station

Facilities and Infrastructure: Equipped with state-of-the-art laboratories, computational resources, and experimental facilities, our research center provides an optimal environment for conducting cutting-edge research. From advanced simulation software to experimental setups, we offer the necessary infrastructure to support diverse research endeavors.

At the core of our mission lies a dedication to pushing the boundaries of mechanical engineering through rigorous research, collaboration, and academic pursuit. We aim to cultivate an environment where curiosity thrives, innovation flourishes, and solutions to complex engineering challenges emerge.

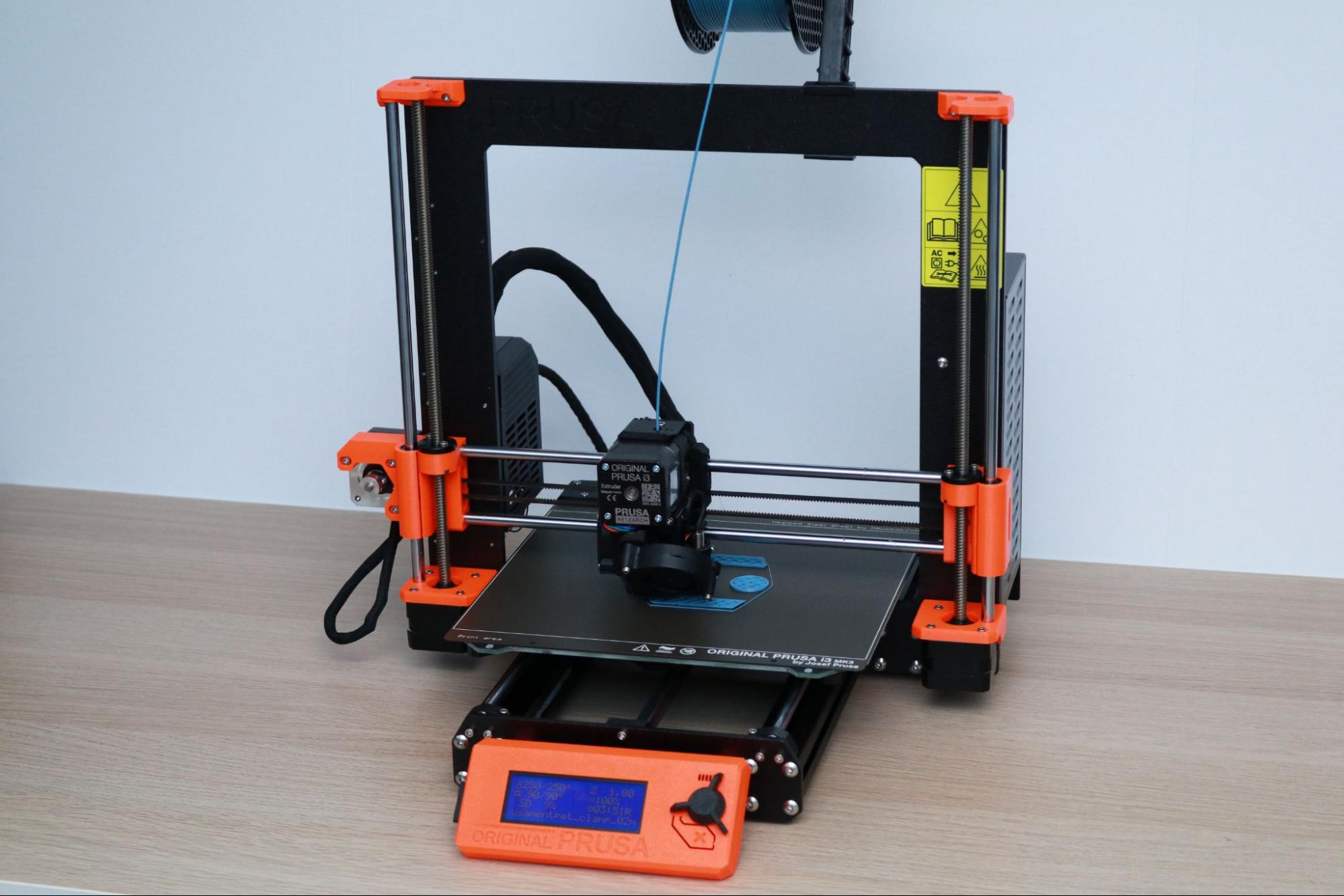

3D Printer

| Build Volume | 25×21×21 cm (9.84″×8.3″×8.3″) |

| Layer height | 0.05 – 0.35 mm |

| Nozzle | 0.4mm default, wide range of other diameters/nozzles supported |

| Filament diameter | 1.75 mm |

| Supported materials | Wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill and other filled materials. |

| Max travel speed | 200+ mm/s |

| Max nozzle temperature | 300 °C / 572 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Extruder | Direct Drive, Bondtech gears, V6 hotend |

| Print surface | Removable magnetic steel sheets(*) with different surface finishes, heatbed with cold corners compensation |

| Printer dimensions (without spool) | 7 kg, 500×550×400 mm; 19.6×21.6×15.7 in (X×Y×Z) |

| Power consumption | PLA settings: 80W / ABS settings: 120W |

c02 Laser cutter

| Technical Parameter | Details |

|---|---|

| Working Size | 1300*900mm |

| Laser Power | 100W CO2 Laser Tube (EFR Laser Tube) |

| Laser Type | CO2 |

| Working Platform | Honeycomb & Blade Bed with Up & Down Table |

| Working Speed | ≤1000mm/s |

| Resolution Rate | ±0.05mm |

| Supported Graphic Format | BMP, PLT, DST, AI, DXF, etc. |

| Cooling Mode | Water Cooling and Protection System |

| Control System | RD Cam System with WIFI |

| Driving System | Stepper Motor |

| Compatible Software | CorelDraw, AutoCAD, Photoshop |

| Working Voltage | AC220V ±10%, 50~60Hz |

| Working Temperature | 0~45°C |

| Working Humidity | 5%~95% (without condensed water) |

| Accessories | Air Compressor, Exhaust Fan |

| Packing Dimension | 142010201100 mm |

| Gross Weight | ≤400 KG |